Research & Development

Innovation strategy

Meeting room ideal for training

For example, our latest lead-free alloys have set the standard in the world of brazing and costume jewellery.Internal or external test centre

Our machines are available for your testing , and the production of small and medium quantities or prototypes.

We can also send a team to your premises to carry our casting operations or to train your staff.Analysis laboratories

We personally check and certify the composition of all our alloys.

> Who is our subcontractin… (201.11 KB)

Continuous investment

Spectrometer NITON – XL3T 980 – GOLDD+

Installed since March 2010 in the modern and functional new premises, each year the METACONCEPT Group’s companies invest in areas such as production, logistics or IT in order to optimise work tools and improve the well-being of its staff whilst increasing productivity.

At the start of 2013 the METACONCEPT Group purchased a portable spectrometer for metal analysis so that it can carry out precise checks on its products that are about to be or are currently being used. This device, designed like a handheld computer, combines technology (touch-screen, tilt display), design, ergonomics, low weight and performance (almost instantaneous measurements, customisable menus, integrated GPS, etc.).

An indispensable and modern device for:

- Analysing metals closely and quickly

- Visually identifying components via cartography

- Detecting potential residual elements contrary to regulations or banned substances

- Checking the exact composition of alloys

- Controlling their quality and ensuring the traceability of substances

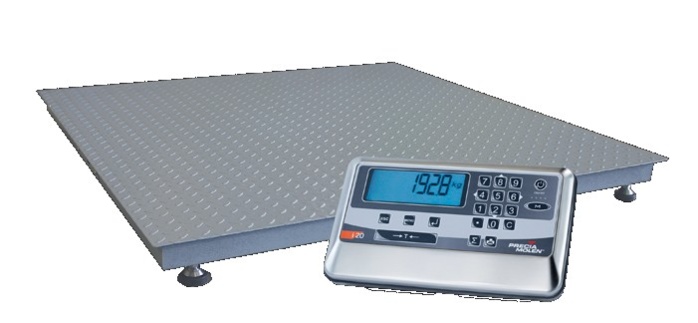

- Approved electronic weighing scale

Approved electronic weighing sale

The METACONCEPT Group is also equipped with:

– A radioactivity detector for receiving and analysing materials guaranteed to be free of any trace of radioactivity.

– An approved electronic weighing scale for metrological use ensuring the correct delivered weight.

Positive investments in the continuous improvement of our quality policy.