Soldering Sticks

Sticks form part of our wide range of filler metals for soft soldering. These products are used for applications such as building and all types of manufacturing. Waste originating from the use of these products can be recycled.

The sticks are made from primary quality metals. Their shape is particularly suited to plumbing work, accessories for sheet metal work and car bodywork. They are also suitable for industrial use in the assembly of various metals such as copper, brass, tin and zinc. The METACONCEPT Group collects used baths, off-cuts, scraps and white metal oxides.

Contact our recycling department to find out more.

This table shows the most commonly used alloys. For other types of alloys, please contact our technical department.

|

Item no.

|

Designation

|

Composition

|

Dimensions

|

Densité g/cm3

|

Solidus

/Liquidus °C |

Approximative weight

|

Packaging

|

|---|---|---|---|---|---|---|---|

|

FE055012

|

Stick META 28

|

Sn28 – Pb72

|

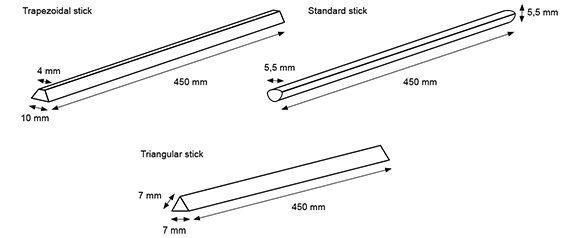

450 x 10 x 4 x 7 mm

|

10,21

|

183°C – 253°C

|

224 g

|

25 kg bundle |

|

FE055014

|

Stick META 30

|

Sn30 – Pb70

|

450 x 10 x 4 x 7 mm

|

10,13

|

183° – 250°

|

222 g

|

25 kg bundle |

|

FE054994

|

Stick META 33

|

Sn33 – Pb67

|

450 x 10 x 4 x 7 mm

|

10,01

|

183°C – 243°C

|

226 g

|

25 kg bundle |

|

FE054991

|

Stick META-ZINC

|

Sn – Pb +

additives |

450 x 10 x 4 x 7 mm

|

10,15

|

181°C – 245°C

|

223 g

|

25 kg bundle |

|

FE055017

|

Stick META 40

|

Sn40 – Pb60

|

450 x 10 x 4 x 7 mm

|

9,72

|

183°C – 225°C

|

213 g

|

25 kg bundle |

|

FE028977

|

Stick SN50

|

Sn50 – Pb50

|

450 x 10 x 4 x 7 mm

|

9,32

|

183°C – 210°C

|

205 g

|

25 kg bundle |

|

FE028980

|

Stick Sn60

|

Sn60 – Pb40

|

450 x 10 x 4 x 7 mm

|

8,91

|

183°C – 190°C

|

195 g

|

25 kg bundle |

|

MF100041

|

Triangular stick*

|

Sn70 – Zn30

|

450 x 7 x 7 mm

|

7,25

|

199°C – 320°C

|

159 g

|

25 kg bundle |

|

FE028962

|

Trapezoidal stick OTALINE

|

Sn – Pb – Zn

|

450 x 10 x 4 x 7 mm

|

9,51

|

170°C – 179°C

|

209 g

|

20 kg bundle |

|

FE100050

|

Triangular stick*

|

Sn95 – Ag5

|

450 x 7 x 7 mm

|

7,45

|

221°C – 223°C

|

163 g

|

25 kg bundle |

|

FE100001

|

Half-round spun stick

|

Sn96,5 – Ag3,5

|

500 x 10 x 12 mm

|

7,4

|

221°C – 230°C

|

181 g

|

20 kg bundle |

|

FE028964

|

Triangular stick*

|

Sn100

|

450 x 7 x 7 mm

|

7,28

|

232°C

|

160 g

|

20 kg bundle |

|

FE100166

|

Triangular stick*

|

Sn100

|

440 x 9 x 9 mm

|

7,27

|

199°

|

160 g

|

10 kg bundle |

(*) Lead-free alloys – European standard no. 2000 / 53 / CE

The dimensions and weights are given for informational purposes only and may vary depending on the production run.

Sn28 – Sn30 – Sn33 sticks

Plumbing, tinware, car bodywork, tinning baths, sheet metal work, coverings.Sn40 sticks

Heating, assembly of mechanical partsSn50 – Sn60 sticks

Creating of and filling tinning baths, assembly of mechanical parts.Sn100 sticks

Casting, surface treatments including tinning cookware, brassware.Sn40 sticks

Sheet metal work, coverings, assembly of mechanical partsOtaline sticks

Used on aluminium and its alloys. Apply Aluflux flux for this application.

The product safety datasheet below is available on request from the METACONCEPT Group.

The parts to assemble must be clean (deoxidised and degreased). Apply the appropriate flux to the parts. Heat the parts using a propane or acetylene torch, or a soldering iron.

The parts must be brought to a temperature of around 15 to 20°C below liquidus.

Melt the filler metal onto the parts being assembled to form a regular bead.

Allow the parts to cool without moving them.

When the parts have returned to room temperature, brush the soldering beads using a metallic brush. If necessary, clean the assembly with clean water or water with a touch of citric or formic acid (1 to 2%).

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

Do not smoke at the workstation.

The workstation must be well ventilated.

Wash your hands when leaving the workstation.

Comments :

Always use a flux suited to the intended use. Contact our technical department to ascertain which product is most suited to your application.