STAR® Alloys Based On Tin And Lead

Tin- and lead-based Babbitt alloys are used to coat bushing bearings for diesel engines, turbines, rolling stock, pumps, presses and various industrial machines. Our Babbitt metals are all made from high quality metals and their composition is strictly controlled using modern analytical techniques. The METACONCEPT Group offers a complete range of specific alloys in small and large ingots, bars and wires.

Have you defined the type of application, the load, the bearing’s dimensions and the shaft’s rotation speed? Our technical staff will be happy to assist you in deciding which Babbitt alloy to choose.

Contact us.

In addition, the METACONCEPT Group collects used baths, off-cuts, scraps and white metal oxides.

Contact our recycling department to find out more.

The table below shows the most commonly used alloys.

|

Item no.

|

Designation

|

Form

|

Solidus/Liquidus

|

Density

g/cm3 |

Brinell*

hardness |

Casting

T° |

|---|---|---|---|---|---|---|

| FB200301 | STAR®CAB Babbitt | Small stamped ingot |

238° – 343°

|

10,25

|

18 à 15°

6,7 à 100° |

360° à 400°

|

| MB201590 | STAR® LAMINOIR N°4 Babbitt code 201 |

Large stamped ingot |

238° – 414°

|

9,75

|

38,2 à 15°

11,2 à 100° |

460° à 550°

|

| MB202590 | STAR® MRS Babbitt code 202 |

Large stamped ingot |

239° – 418°

|

9,7

|

38,2 à 15°

11,2 à 100° |

445° à 550°

|

| FB111300 | STAR® OH AVIATION Babbitt code 111 |

Small stamped ingot |

238° – 333°

|

7,32

|

25 à 15°

12 à 100° |

355° à 405°

|

| MB112590 | STAR® DIESEL 88 Babbitt code 112 |

Large stamped ingot |

238° – 344°

|

7,38

|

27,2 à 15°

14,1 à 100° |

370° à 410°

|

| MB113590 | STAR® DIESEL L Babbitt code 113 |

Large stamped ingot |

235° – 351°

|

7,35

|

35 à 15°

14,5 à 100° |

390° à 480°

|

| MB100593 | STAR® T81 Babbitt | Large stamped ingot |

235° – 355°

|

7,35

|

28 à 15°

9,5 à 100° |

NC

|

| MB106590 | STAR® WM80 Babbitt Code 106 |

Large stamped ingot |

183° – 400°

|

7,51

|

32 à 15°

15 à 100° |

390° à 450°

|

| MB100594 | STAR® JA Babbitt | Large stamped ingot |

235° – 380°

|

7,34

|

41 à 15°

13 à 100° |

480° à 530°

|

(*) 500 kg load, 10 mm block, 15 sec

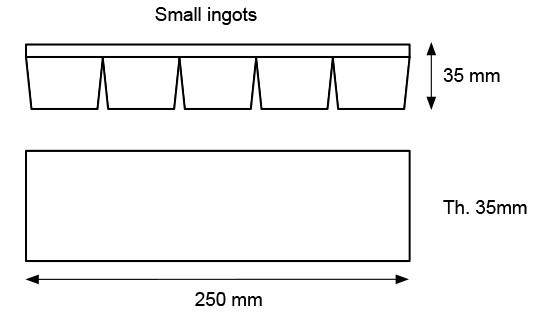

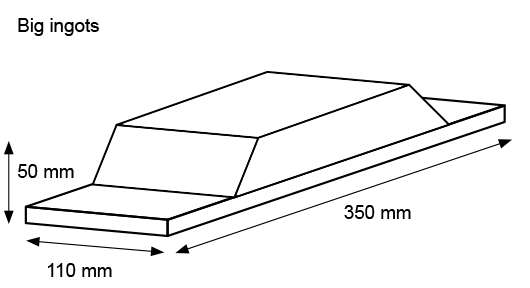

Dimensions and weights are given for informational purposes only and may vary depending on the production run.

|

Name

|

Designation

|

Uses

|

|---|---|---|

| CAB Babbitt | Lead-based, copper-free alloy | Specially designed for seasoning cable ends |

| Laminoir N°4 Babbitt code 201 | Lead-based alloy | Machines working under heavy loads with repeated shocks and at slow speeds (rolling machine, mill, crusher, etc.) |

| MRS Babbitt code 202 | Lead-based alloy | Corresponding to a very wide scope of use Bearings of heavy machinery, low speeds and heavy loads |

| OH AVIATION Babbitt code 111 | Alloy with 90% tine, guaranteed lead-free* | Machines operating at high speeds and with heavy loads (connecting rod head, thin bearings, fast car engines, turbine reducers, etc.) |

| STAR DIESEL L 88 Babbitt code 112 | Alloy with 88% tine, guaranteed lead-free* | Marine diesel engines (SULZER approved), rail traction equipment, electric motors, turbines, other high speed motors, etc.) |

| STAR DIESEL L Babbitt code 113 | Alloy with 81% tine, guaranteed lead-free* | Diesel and electric motors, bearings for hydraulic turbines when the expected thickness of the metal is greater than 6/10 mm |

| WM80 Babbitt code 106 | Alloy with 80% tin | All bearings operating at high speeds with medium loads and all uses requiring a high tin content alloy in standard operating conditions |

| STAR® T81 Babbitt | Alloy with 81% tin | Bushing or shaft bearings, when the operating conditions are average; steam turbine idler bearings |

| STAR® JA Babbitt | Alloy with 81% tin, lead-free* | Machines operating at high speeds and with heavy loads, connecting rod heads, thin bearings, turbines, ALSTOM JEUMONT POWER approved |

(*)Lead-free alloys – European standard no. 2000 / 53 / CE

|

Item no.

|

Designation

|

Packaging

|

Uses

|

Special characteristics

|

|---|---|---|---|---|

|

SO001000

|

ETAMALLOY® powder | 1 kg box | For tinning bases before babbitting Particularly effective with bases that are known to be difficult to tin, such as special steels and even cast iron. | ETAMALLOY® trademark |

|

SO001002

|

ETAMALLOY®SN63 paint | 1 kg box | For tinning bases before babbitting | ETAMALLOY® trademark |

|

SO0010001

|

ETAMALLOY®SN100 paint | 1 kg box | For tinning bases before babbitting | ETAMALLOY® trademark |

|

FO100000

|

Copper phosphorous | 50 kg box of shots |

For mixing the Babbitt alloy | NC |

|

UN100000

|

ETAMALLOY® cement | 1 kg box | To prevent leakage of the alloy during casting, it is necessary to ensure the watertightness of the assembly using ETAMALLOY® cement | ETAMALLOY® trademark |

|

EG001003

|

ETAMALLOY® flux | 6 kg can | Brazing flux to be applied just prior to tinning. The base must be cleaned(degreased and pic | ETAMALLOY® trademark |

|

FB710001

|

ETAMALLOY®33 rod | Box of 16 rods | 33% tin-lead alloy for assembly repairs | ETAMALLOY® trademark |

|

FB710005

|

ETAMALLOY®80 rod | Box of 16 rods | 60% tin-lead alloy for assembly repairs | ETAMALLOY® trademark |

|

MF100189 MF100176

|

Solid Babbitt wire Sn89 – Sb7.5 – Cu3.5 – Ø 1.6 mm and 3.2 mm |

10 kg DIN spool |

For external metallic projection (metal spraying) | NC |

|

SUR DEMANDE

|

Solid Babbitt wire Ni95 – Al5 Ø 1.6 mm and 3.2 mm |

10 kg DIN spool |

For external metallic projection (metal spraying) | NC |

The product safety information sheet below is available upon request from the METACONCEPT Group.

The implementation procedure is specific to the alloy and its application. Contact the METACONCEPT Group’s sales department who, after you’ve selected the Babbitt alloy, will provide the appropriate implementation sheet.

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

– Do not smoke at the workstation.

– The workstation must be well ventilated.

– Wash your hands when leaving the workstation.

Comments :

Always use a flux suited to the intended use. Contact our technical department to ascertain which product is most suited to your application.

All of the information contained in this document is provided for informational purposes only and the METACONCEPT Group will not be held liable for it.

What is a Babbitt Alloy?

Antifriction alloys are alloys consisting of tin, antimony, lead and copper with a soft, low melting point phase and a hard particle phase. Their inventor was an American metallurgical engineer, Isaac Babbitt (hence the name Babbitt Metal). Several techniques exist to obtain anti-friction alloys: by casting, by coating or by spraying. They have a density of 7.38 kg/m. Depending on the components, they can be made of tin-based antifriction alloys, cadmium-based antifriction alloys or lead-based antifriction alloys.

Antifriction alloys are used in the production of plain bearings. When a sliding bearing is in operation, it generates a lot of friction against the heavy load shaft which rotates at high speed. An alloy structure with hard matrix soft spots and soft matrix hard spots is used to reduce this friction. After a period of development, the soft matrix becomes convex on the outside of the hard point and concave on the inside. This leads to the formation of a small gap between the sliding surfaces, which allows the storage of lubricating oil and thus the reduction of friction. The hard point serves as a support, which allows the bearing to function properly.

Examples of Babbitt Alloys

Here are some examples of babbitt alloys used to reduce friction between mechanical parts.

Tin-Based Babbitt Alloy

This is the tin-based alloy consisting of 2% to 6% copper, 3% to 15% antimony and less than 1% cadmium. Antimony is present in the composition of the soft phase matrix of the alloy, which is predominantly tin. The hard points are made up of metallic elements such as Cu3Sn and SnSb. The advantage of tin-based babbitt alloys is that they provide better thermal conductivity. In addition, they offer good plasticity and a low coefficient of expansion and friction.

Despite this, the tin-based alloy is less resistant to fatigue. It is suitable for casting large machine bearings such as those in a steam turbine, a high-speed, high-horsepower steam engine and a machine tool.

Lead-Based Babbitt Alloy

Lead-based babbitt alloys consist of 5% to 15% tin, 10% to 20% antimony and small amounts of copper, arsenic and other alloying elements. The lead that makes up the majority of the soft matrix contains an antimony-based rolling alloy, resulting in a solid solution. The hard points, on the other hand, contain metal compounds such as Cu3Sn and SnSb.

Compared to the tin-based babbitt alloy, the lead-based babbitt alloy is less strong and less resistant. It has a relatively high coefficient of friction and is less resistant to impact. Despite this, it is more affordable and is suitable for bearings with an operating temperature below 120°C. Thus, it can be used in compressors, mills, motors and vacuum pumps.

The tin-based babbitt alloy has the advantage of a high hardness and strength ratio compared to lead alloy. It is more resistant to corrosion. For these reasons and many others, tin-based alloys are widely used in industry.

The peculiarity of babbitt alloys is that they have difficulty withstanding high pressures. They are usually used in large bearing rings for shaft seals, bearings, machine spindles, shaft sleeves in cement. In some machines, they can also replace brass.