Costume/fancy Jewellery Arts And Crafts Alloys

The METACONCEPT Group offers a wide range of products designed for the costume/fancy jewellery and arts and crafts markets. The range includes alloys in the form of bars, ingots and wires as well as chemical products such as powders, deoxidising tablets and fluxes. Finally, a range of silver creams complements the above-mentioned products for use in assemblies and for modifications.

Our costume/fancy jewellery flat bars are specially designed for all types of arts and crafts works. Created from primary metals, they generate minimal slag and give an impeccable surface appearance. They especially meet the requirements of clients using a centrifugal or gravity process to produce their parts. Our range also comprises lead-free products chosen for their food-safe properties and which are well suited to these applications.

The products covered by this sheet are all tin-based alloys that have been specially developed for the creation of parts using centrifugal processes. Some fashion items or pieces of costume jewellery can also be produced using this centrifugal process with zamak or polyurethane resin. Have you defined the type of application? Contact us. Our technical staff will be happy to assist you in choosing the most suitable alloy.

In addition, the METACONCEPT Group collects used baths, off-cuts, scraps and white metal oxides.Contact our recycling department to find out more.

|

Intem no.

|

Designation /

Composition |

Dimensions

|

Density

g/cm3 |

Solidus /

Liquidus |

Recommented

temp. |

weight

|

Packaging

|

|---|---|---|---|---|---|---|---|

| FE028953 | Flat bar Sn40 – Pb51 – Sb5 – Bi3 – Cu1 |

7 x 22 x 395 mm

|

9,64

|

185°C – 215°C

|

320°C

|

600 g

|

25 kg box

|

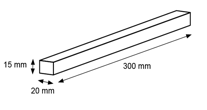

| FE028950 | Bar BIJAL 72 |

15 x 20 x 300 mm

|

8,09

|

173°C – 215°C

|

310°C

|

720 g

|

20 kg box

|

| FE051313 | Bar BIJAL 88 |

15 x 20 x 300 mm

|

7,64

|

205°C – 208°C

|

270°C

|

NC

|

20 kg box

|

| FE011205 | Flat bar Sn92 – Sb7,5 – Cu0,5 |

7 x 22 x 395 mm

|

7,36

|

235°C – 244°C

|

350°C

|

580 g

|

20 kg box

|

| FE028959 | Flat bar Sn93,5 – Pb4 – Sb1 – Cd1,5 |

7 x 22 x 395 mm

|

7,46

|

234°C – 245°C

|

315°C

|

550 g

|

20 kg box

|

| FE056491 | Flat bar Sn95 – Sb4,5 – Cu0,5 |

7 x 22 x 395 mm

|

7,25

|

230°C – 240°C

|

340°C

|

550 g

|

20 kg box

|

| MF100183 | Bar ECOBIJAL less than 50 ppm lead |

20 x 45 x 380 mm

|

7,40

|

220°C – 230°C

|

310°C

|

2,6 kg

|

21 kg box

|

| MF100193 | Bar ECOBIJAL less than 50 ppm lead |

20 x 45 x 380 mm

|

7,40

|

220°C – 228°C

|

270°C

|

2,5 kg

|

21 kg box

|

The lead-free alloys, references MF100183 and MF100193, both with pb content less than 50 ppm, have been created and developed by the METACONCEPT Group and improved with the assistance, over several months, of engineers specialising in the metallurgy of non-ferrous metals. The improvements made to these alloys make it possible to create any kind of part, even smooth parts, with an exceptional surface quality.

The ECOBIJAL CC – 50 PPM improves the quality of the surface treatment even further and the rate of non-compliant parts after treatment is less than 5%. Both items have been vetted by a major high-end costume jewellery manufacturer. They comply with regulations and are environmentally-friendly.

The dimensions and weights are always given purely for informational purposes and may vary depending on the production run.

Complementary products

|

Designation

|

Density

|

Solidus / Liquidus

|

Packaging

|

Comments

|

|---|---|---|---|---|

|

Solid wire Sn – Pb – Bi

|

9,38

|

145°C- 165°C

|

500 g spool

|

Low melting temperature solder wire for repairs or the creation of joints on centrifugal parts or jewellery Ø available: 1 – 1.5 – 2 mm

|

|

Solid wire Sn – Pb – Cd

|

8,83

|

145°C Eutectic

|

500 g spool

|

Low melting temperature solder wire for repairs or the creation of joints on centrifugal parts or jewellery 1 mm Ø available

|

|

Solid wire Sn – Ag – Cu

New lead-free wire |

7,41

|

217°C Eutectic

|

500 g spool

|

Low melting temperature solder wire for repairs or the creation of joints on centrifugal parts or jewellery 0.5 and 0.7 mm Ø available

|

|

Tin/bismuth soldering cream

|

8,68

|

138°C Eutectic

|

3 cc syringe

|

Low melting temperature cream for repairs or the creation of joints on centrifugal parts or jewellery

|

|

Tin/silver brazing cream

|

7,39

|

221°C Eutectic

|

3 cc syringe

|

Slightly higher melting point, often used to repair jewellery chains because of its good mechanical resistance

|

|

Flux POWERFLUX

|

NC

|

NC

|

100 g pot

|

Used with solid wire, low melting temperature. Ecological flux

|

|

Deoxidising powder T010

|

NC

|

NC

|

100 g pot

|

Oxide separation powder

|

|

Deoxidising tablet LF

|

NC

|

NC

|

200 g bottle

|

Lead-free metallic tablets for metallic oxide elimination.

|

Costume/fancy jewellery

- High tin content alloys

- Inevitable preference for lead-free alloys with less than 50 ppm of lead (ECOBIJAL range)/ROHS directive

- Surface treatment: yes

Tinware

- Tin-antimony alloy

- Surface treatment: no

Figurines

- Tin-antimony alloy

- Surface treatment: yes

Modelling

- High tin content alloys and Sn40 – Pb51 – Sb5 – Bi3 – Cu1 alloys for creating extremely thin parts such as hub caps, car steering wheels, etc.

- Surface treatment: yes

Decorating/furniture

- Lead-tin or zamak alloy

- Surface treatment: yes

Fashion accessories, leather goods

- Tin-antimony, zamak alloy

- Surface treatment: yes

Mechanics, electricity

- Holding parts, mainly zamak

The product safety datasheet below is available upon request from the METACONCEPT Group.

Fusion in a tank or crucible

It is advisable to empty the crucible of one third of its metal volume before refilling it with new alloys or with “cores”.

Fill it up to the correct level, allow the bath to return to its original temperature then mix the alloy well by creating a vortex Remove oxides present on the surface using a suitable skimmer and place them in the container provided for this purpose.

Contact our recycling department to obtain these dedicated watertight containers free of charge.

For better deoxidisation of the bath, use metallic deoxidising tablets or T010 powders.

The temperature of the crucible must be checked regularly and be as constant as possible.

The metal must be poured into a hot mould (silicon mould) for the creation of parts that are free from micro-porosities. An excessive temperature will reduce the life of the mould. In addition, the quality of the part will be significantly reduced. A temperature that is too low will reduce the fluidity and may create deficiencies in parts cast in this way.

As metal segregation leads to the solidification of the alloy, you are advised to mix the bath vigorously before its first daily use.

Before adding the bars to the molten metal, make sure that they are not wet and are free of external elements (dust, paper, glue, etc.).

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

Do not smoke at the workstation.

The workstation must be well ventilated as the fumes emitted during the melting process are dangerous if exposure limits are exceeded.

Wash your hands when leaving the workstation.

You are advised to have alloy waste collected by a licensed professional. The METACONCEPT Group offers a recycling service via watertight metal containers.

Comments

All of the information contained in this document is provided for informational purposes only and the METACONCEPT Group shall not be held liable for it.