Centrifugal Casting Equipment

Sale or subcontracting of machines

As the exclusive NICEM distributor in France, the METACONCEPT Group offers a complete modular range of professional machines for all your casting needs. Designed to streamline the work of the operator, their compact size combined with their unrivalled performance makes these machines indispensable for the production of low and medium quantities. These machines are offered for sale or on a subcontractual basis at our premises.

VULCANISER

Automatic vulcaniser for the production of silicones, with insulated heated plates, head and protection shield for guaranteed energy savings.

Advantages

- Oleodynamic system with auto-pump

Automatic pressure adjustment during the operating cycle - Digital pyrometer for temperature control

Vulcanisation cycle timer with a micro-processor and stable memory display - Cycle programming up to 99 hours and 59 minutes

- Plates opened via solenoid valves

- Double button closure

- Smoke extraction outlet

CENTRIFUGE

Automatic electronic centrifuge with a workstation, featuring a patented insulated protective screen at the start of the cycle.

Advantages

- Extremely convenient mould loading

- Instantaneous machine start-up

- Speed and braking controlled via a “frequency convertor”

- Standard, reliable, asynchronous three-phase motor

- Adjustment of all components via a convertor

- Convertor controlled via a potentiometer or a 10-speed electronic programmer

- Smoke extraction outlet

FURNACE

An automated electric furnace for melting zinc alloys, complete with an insulated cover and protective screen.

Advantages

- A patented heating unit: interchangeable without touching the structure of the furnace

- Total circuit protection against excess temperatures

- Speed and braking controlled via a “frequency convertor”

- Two coupled digital pyrometers guarantee more accurate settings and a perfect temperature

- Cycle programming up to 99 hours and 59 minutes

- Smoke extraction outlet

We also offer a range of accessories:

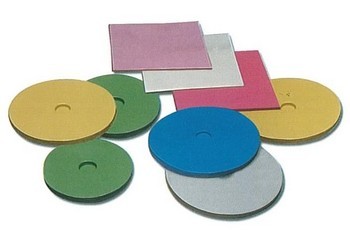

- Silicone moulds for creating imprints

- Decorative resins

- Centrifugal casting equipment

We also offer a complete range of accessories:

- Centring units

- Cutters

- Polishing buffs

- Deburring cones

Think about the METACONCEPT group's fine art alloys

- centrifugal_casting_range_brochure_metaconcept.pdf (2.64 MB)

- Arts_and_craft_alloys_metaconcept_data_sheet (157.84 KB)

For the technical specifications of the models in the range, please contact our sales department

Create your own prototype

Subcontracting at our premises

Do you want to produce low and medium quantities or create one or several prototypes but have neither the time nor the resources to invest in casting equipment?

Then why not produce your metallic parts directly in our technical laboratory?

Advantages

- No investment in a machine

- Quick turnaround time

- Operational subcontracting

- Cutting-edge equipment

- No fixed price

- Parts supplied “ready to use”

To make a reservation or for more information, contact us

download_subcontract_metaconcept.pdf (201.11 KB)