Blowpipe Strips

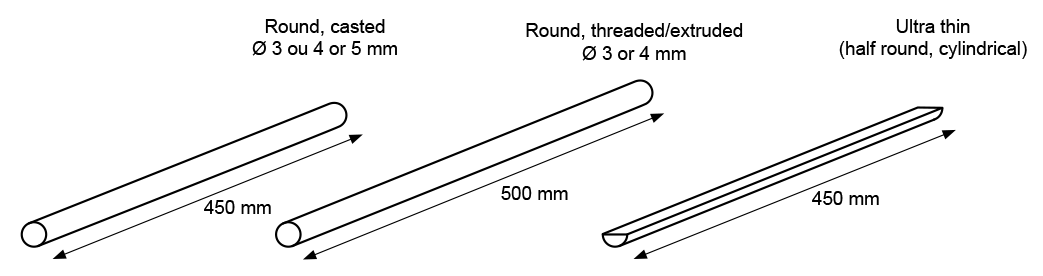

Blowpipes form part of the METACONCEPT Group’s vast range of filler metals including bars and flat bars as well as solder wires and fluxes. These products are used in applications such as the manufacture and repair of heat exchangers and stained glass.

Waste originating from the use of these products can be recycled. Contact our recycling department to find out more. The METACONCEPT Group’s blowpipes are made from primary quality metals. Their profile is particularly suited to stained glass work and repairs to car radiators and construction equipment.

They can be used to assemble various metals such as copper, brass, tin and zinc in industrial settings. Their new very thin shape makes it possible to solder very small parts.

|

Item no.

|

Designation

|

Dimensions

|

Density g/cm3

|

Solidus / Liquidus

|

Packaging

|

|---|---|---|---|---|---|

|

FE054935

|

Casted blowpipe META 30

|

5 x 450 mm

|

10,13

|

183°C – 250°C

|

25 kg bundle

|

|

FE020514

|

Ultra thin, casted blowpipe Sn 30

|

5 x 450 mm

|

10,13

|

183°C – 250°C

|

20 kg bundle

|

|

FE100035

|

Extruded blowpipe Sn 60

|

3 x 450 mm

|

8,81

|

183°C – 190°C

|

25 kg bundle

|

|

FE040870

|

Extruded blowpipe Sn 60

|

4 x 450 mm

|

8,81

|

183°C – 190°C

|

20 kg bundle

|

|

FE100038

|

Extruded blowpipe Sn 60

|

5 x 450 mm

|

8, 81

|

183°C – 190°C

|

25 kg bundle

|

|

MF053221

|

Extruded blowpipe Sn 97 – Cu 3

|

5 mm

|

7,33

|

230°C – 250°C

|

10 kg bundle

|

Fluxes for blowpipes

|

Item no.

|

Designation

|

Packaging

|

Information

|

Sectors

|

|---|---|---|---|---|

| DE031855 | Flux PC1 – 250ml | Box of 24 pots | Zinc chloride-based | Car radiators |

| STOSMETA | Flux META 2005 | 45 kg can | Mineral flux | Car radiators |

| STOO2010 | Flux META 2010 | 35 kg can | Organic flux | Car radiators |

| CO024544 | Flux POWERFLOW – 100 g | Box of 20 pots | Hydrogen chloride-based | Stained glass, building |

Stained glass (Blowpipes Sn 60)

- Manufacturing and catering

- Assembly of lead profiles

Repair of car radiators and construction equipment (normal or ultra-thin blowpipes Sn 30)

The product safety information sheet below is available upon request from the METACONCEPT Group.

Propane or oxyacetylene blow torch > Car radiators

Soldering iron > Stained glass

The parts being assembled must be clean (deoxidised and degreased).

First, apply the appropriate flux to the parts.

Heat the parts. The parts must be brought to a temperature of around 15 to 20° above liquidus.

Melt the filler metal onto the parts being assembled to form a regular bead.

Allow the parts to cool without moving them.

When the parts have returned to room temperature, brush the soldering beads using a wire brush.

If necessary, clean the assembly with fresh water or water with a touch of citric or formic acid (1 to 2%).

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

Do not smoke at the workstation.

The workstation must be well ventilated.

Wash your hands when leaving the workstation.Comments :

Always use a flux suited to the intended use. Contact our technical department to ascertain which product is most suited to your application.All of the information contained in this document is provided for informational purposes only and the METACONCEPT Group will not be held liable for it.